BPS-K600 Mold Breakout Prediction System Private individual

6 months ago Business & Mechinery Dhaka 105 viewsLocation: Dhaka

Price: Contact us

Overview:

The BPS-K600 continuous casting mould breakout prediction system is developed by Wuhan CenterRise M&C Measuring Co., Ltd. It adopts artificial neural network and combines with traditional artificial intelligence and information processing technology to overcome the defects of traditional logic-based prediction models. It has the functions of self-adaptation, self-organization and real-time learning.

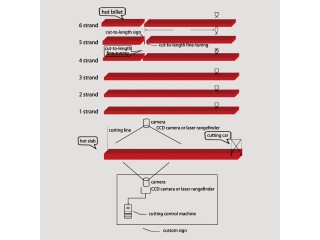

The breakout prediction system has an optimized industrial network structure. According to the distribution and change rules of the temperature field of the mold, it can track and respond to the breakout process in real time. It can learn and judge by itself, and provide early warning information for on-site operations. It can effectively prevent the occurrence of breakout accidents, greatly reducing the cost and improving the safety factor of continuous casting.

The system is suitable for all kinds of continuous casting machines such as square billet, round billet, rectangular billet and slab.

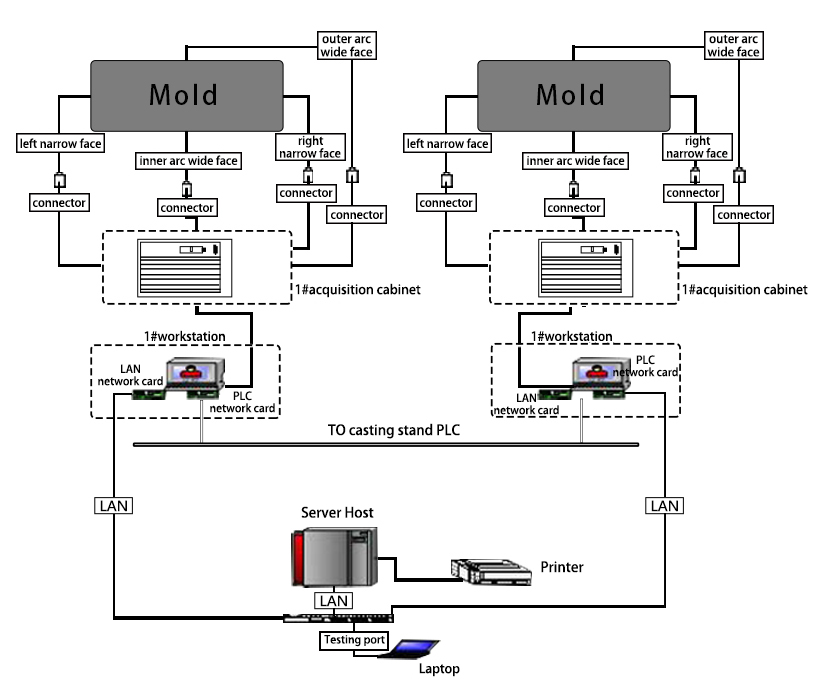

Block Diagram of Breakout Prediction System

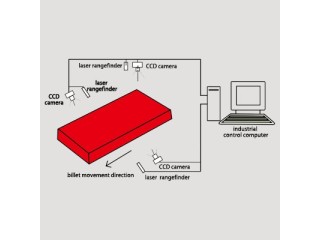

The composition of the system

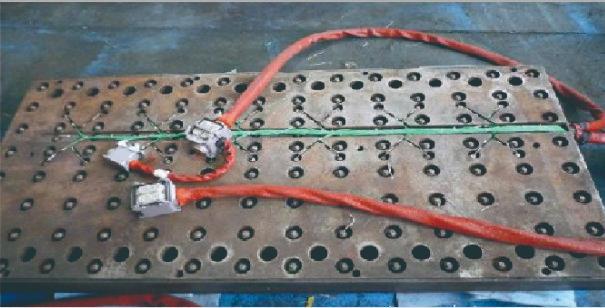

Thermocouple: according to the on-site conditions of the mold, water tank, bolts and mold frame to desgin

Front-end acquisition system: Multi-module acquisition chain, industrial Ethernet interface, high-speed embedded processing module

Working platform: Real-time display of mold temperature field status, online analysis and prediction of mold breakout

Server: Data exchange and storage management, reporting and printing system, with data analysis and self-learning functions

The Main technical parameters

Data sampling: the sampling frequency of K-type/T-type thermocouple can up to 10HZ

Accuracy of temperature measurement: ±0.25℃

Support communication protocol: Industrial Ethernet (TCP/IP),PROFIBUS-DP,CANopen

Executive standard: DE0411 Standard Class III/1EC584/IEC1515

Transmission speed: 100M/bps

The composition of the software

Online monitoring software for breakout prediction

Offline query software for breakout prediction

Data recovery and self-learning software packages

Data acquisition and monitoring software

The software package of mold thermal status display

The functions of the system

Real-time data acquisition, data analysis and judgment

Automatic selection of steel grade’s alarm parameters

Real-time dynamic picture monitoring

Prediction alarm and information display of breakout signs

Automatic deceleration after alarm

Historical data storage and historical trend graph display

Automatic report generation and printing

Alarm prediction and pattern recognition of unknown steel grades by neural network

Dynamic real-time temperature profile prediction

Mould heat flow field display

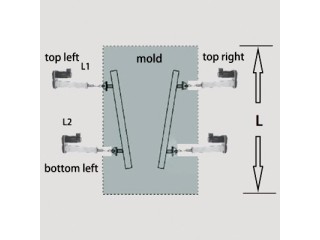

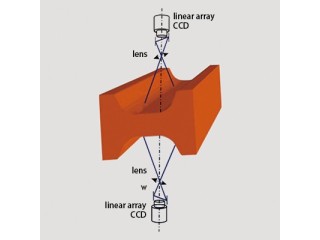

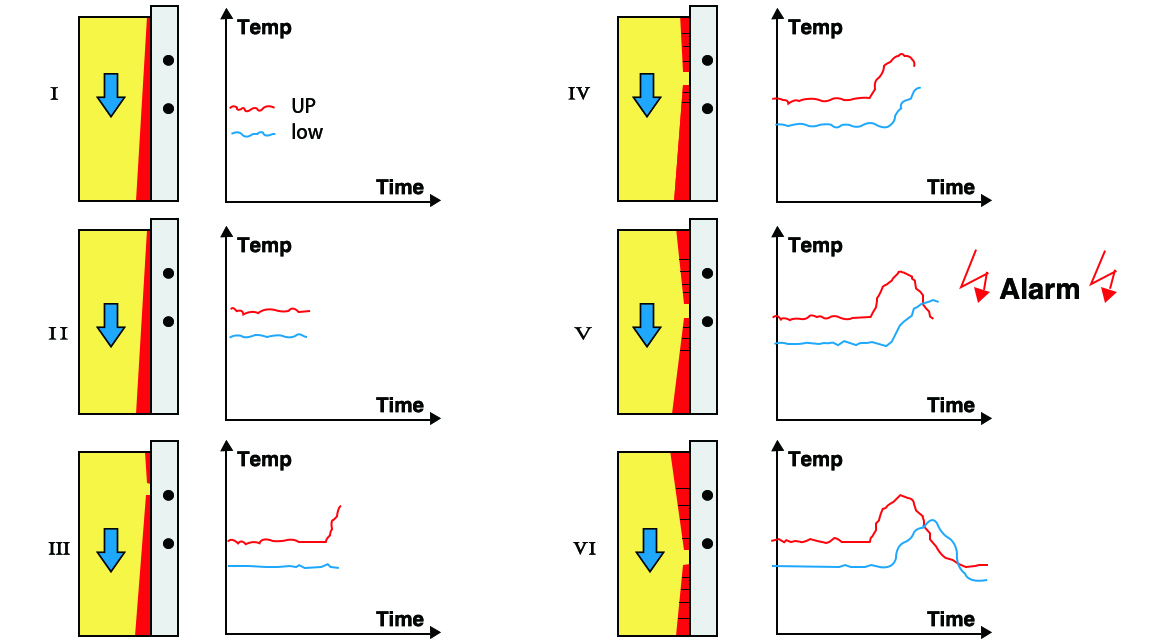

FIG 1:Typical process of mold breakout prediction

The features of the system

1. Reasonable design of temperature measurement point and professional protection front-end acquisition system, and complete installation and calibration tool components.

2. The system has strong adaptability and can meet the transformation of various structural continuous casting machines.

3. High-speed data communication, using industrial network to form an independent local area network for each workstation and server. It can realize high-speed data transmission of alarm files, alarm parameters, and other databases.

4. The combination of artificial neural network and intelligent forecasting model improves the alarm accuracy of breakout forecasting.

5. Historical data storage and historical trend graph display, historical reports, historical alarm legend printing, real-time alarm data printing.

6. Provide a local area network interface, which can realize the storage and forwarding of alarm files, and the input and output of offline alarm data.

7. Remote Web browsing can be achieved according to customer needs.

8. Can be seamlessly connected with MES-C220 mould expert system.

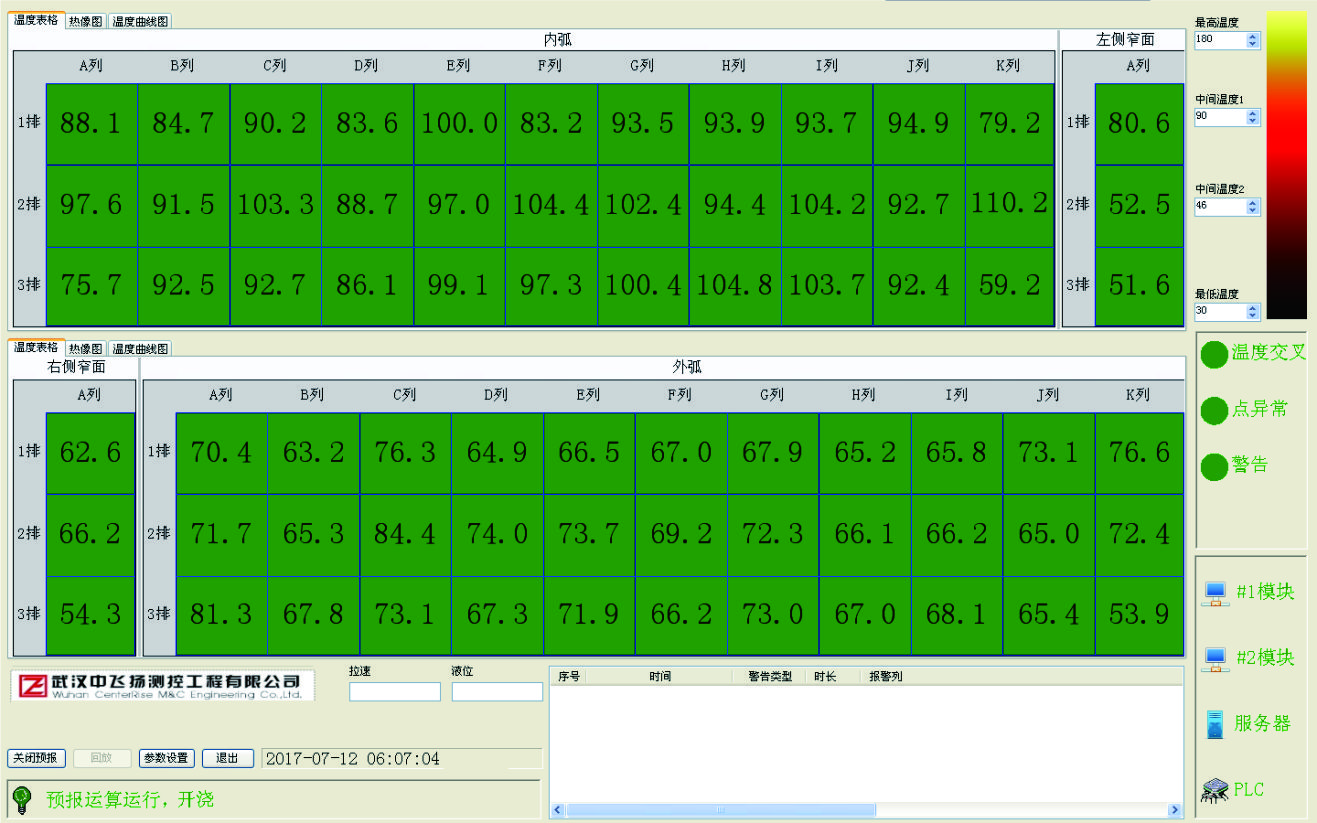

FIG 2: Software interface of breakout prediction

FIG 3: Thermocouple collection box

FIG 4: Thermocouple installation